CHANCE® Helical Pulldown® Micropiles

Developed in 1997 for sites with especially weak surface soils, this patented innovative application of the helical pile integrates portland-cement-based grout to increase the section properties of the shaft. The Helical Pulldown Micropile (HPM) brings the advantages of the pre-engineered helical pile to higher load applications, providing compression loads of 20,000 lbs. to 400,000 lbs. per pile. By “pulling down” a special flowable grout as the micropile foundation is screwed into the soil, these helical micropiles create a deep foundation with both a friction-bearing central shaft and end-bearing helical plates in competent substrata.

Developed in 1997 for sites with especially weak surface soils, this patented innovative application of the helical pile integrates portland-cement-based grout to increase the section properties of the shaft. The Helical Pulldown Micropile (HPM) brings the advantages of the pre-engineered helical pile to higher load applications, providing compression loads of 20,000 lbs. to 400,000 lbs. per pile. By “pulling down” a special flowable grout as the micropile foundation is screwed into the soil, these helical micropiles create a deep foundation with both a friction-bearing central shaft and end-bearing helical plates in competent substrata.

Benefits of the CHANCE® Helical Pulldown® Micropile include:

- Resistance to buckling in weak surface soils

- Higher load capacity

- Stiffer pile (deflects less at a particular load)

- Additional corrosion protection in aggressive soils

How it works

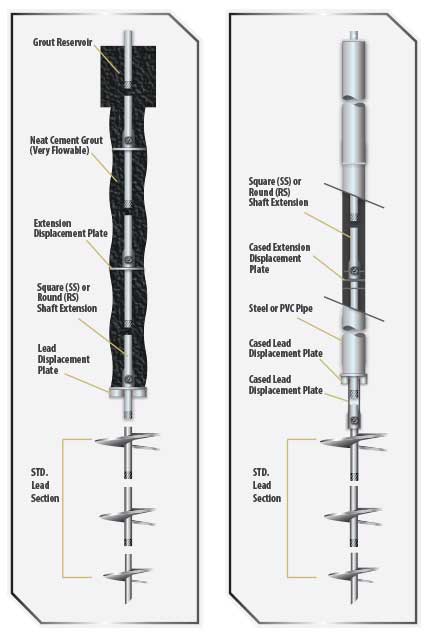

The Helical Pulldown® Micropile is a system for constructing a grout column around the shaft of a standard Helical Pile system. To begin the process, a helical pile is placed into the soil by applying torque to the shaft. The helical shape of the bearing plates creates a tremendous pulling force that keeps the anchor advancing downward into the soil. After the lead section with the helical plates penetrates the soil, a lead displacement plate and extension are bolted onto the shaft.

Resuming torque on the assembled shaft advances the helical plates and pulls the displacement plate downward, forcing soil outward to create a cylindrical void around the shaft. From a reservoir at the surface, a flowable grout immediately fills this void, surrounding and encapsulating the shaft. Additional extensions and displacement plates are added until the helical bearing plates reach competent load-bearing soil. The Helical Pulldown® Micropile displaced the soil around the shaft, eliminating the need to remove spoils from the site.

See how CHANCE Micropile Foundations were used in these case studies: