CHANCE® Helical Anchors

Since the early 1960s, CHANCE® Helical Anchors have been used in the electric transmission industry as the primary guy anchor solution. Today, CHANCE® Helical Anchors are finding increased popularity in civil construction applications because of the versatility and cost-effectiveness of this uplift (tension) restraint solution. CHANCE® Helical Anchors extend bearing plates through soft, loose or expansive surface soils into stable strata with minimal disturbance. Discover how helical anchor systems are the predictable, cost-effective, quickly installed alternative to traditional uplift restraint methods.

Since the early 1960s, CHANCE® Helical Anchors have been used in the electric transmission industry as the primary guy anchor solution. Today, CHANCE® Helical Anchors are finding increased popularity in civil construction applications because of the versatility and cost-effectiveness of this uplift (tension) restraint solution. CHANCE® Helical Anchors extend bearing plates through soft, loose or expansive surface soils into stable strata with minimal disturbance. Discover how helical anchor systems are the predictable, cost-effective, quickly installed alternative to traditional uplift restraint methods.

A new look at helical anchor systems

Helical anchors are commonly selected for earth anchoring applications because they are quick to install and can be proof-tested and loaded immediately with no concrete to cure or de-watering of the excavation to deal with. Helical screw anchors are often chosen over traditional anchoring methods such as concrete deadmen or grouted anchors in order to overcome limited accessibility or the presence of a high water table.

Quick, controlled installation

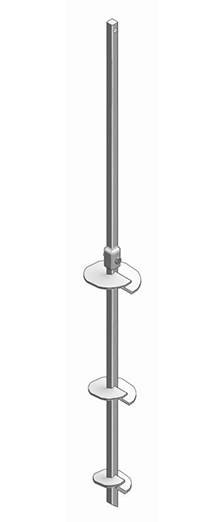

A helical anchor is used to resist tensile loading. For these tension only anchors, square shaft helical anchors are the logical choice. The helical anchor is segmented with helical bearing plates welded to a central steel square shaft. Load is transferred through the shaft to the soil through the bearing plates. CHANCE anchors are coupled together with couplings, and the only limit to installation depth for these anchors is soil density. Engineers can achieve whatever depth makes sense economically.

Since the plates are helical, they do not auger, but rather screw into the soil with minimal disturbance. Helical bearing plates have a standard 3" pitch and are spaced at far enough distances from enough apart that they bear load independently of each other; therefore, the load capacity of one is not influenced by adjacent plates.