WHY USE IT?

In order to support the entire rebar cage vertically within the drilled shaft and provide proper clearance between the rebar reinforcement and the earthen surface at the bottom of the shaft. The encapsulation of the ends of the vertical rebar provides added corrosion protection.

BARBOOT

A simple and economical method of supporting and spacing vertical cage reinforcement at the base of drilled shafts.

APPLICATIONS

- Bridge Foundations

- Building Foundations

- Retaining Wall Foundations

- Street Light Foundations

- High Mast Foundations

- Transmission Line Foundations

- Sub-station Foundations

- Tower Foundations

- Slurry Walls

ADVANTAGES

- Saves time and money

- Easy installation

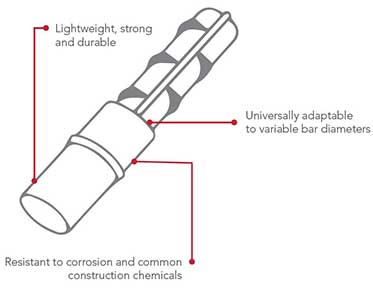

- Universally adaptable to variable size bar diameters (one size fits all)

- Self-locking

- Lightweight, yet strong and durable

- Engineered with the contractor in mind

- Made of high-density plastic, resistant to corrosion, and chemicals common to construction

- Economical to use

- Indefinite shelf-life and easily stored

CONSTRUCTION BENEFITS

- Protects from bar end corrosion.

- Ensures that the bar reinforcement is properly spaced and supported within the confines of the drilled shaft or excavation.

- Provides quality assurance of the contractor’s performance for the engineer and owner.

BARBOOT MINIMUM PLACEMENT RECOMMENDATIONS

- Equally space boots around bottom of the cage

- Use one Barboot per 1500 lbs. of steel cage weight; minimum of one Barboot every other vertical bar

Guiding rebar cage into drilled shaft with Barboots attached

| Model | Cover | Bar Size | Packaging | Weight |

| BB711 | 3.0" | #5 - #14 | 50 | 29 lbs |

| BB711FED* | 3.0" | #5 - #14 | 50 | 29 lbs |

* Product designed specifically for FHWA & DOT projects

Attaching Barboot

Rebar cage staged with Barboot supports attached

Lorem ipsum